| Portfolio of RUBEN BORUP |

|

|

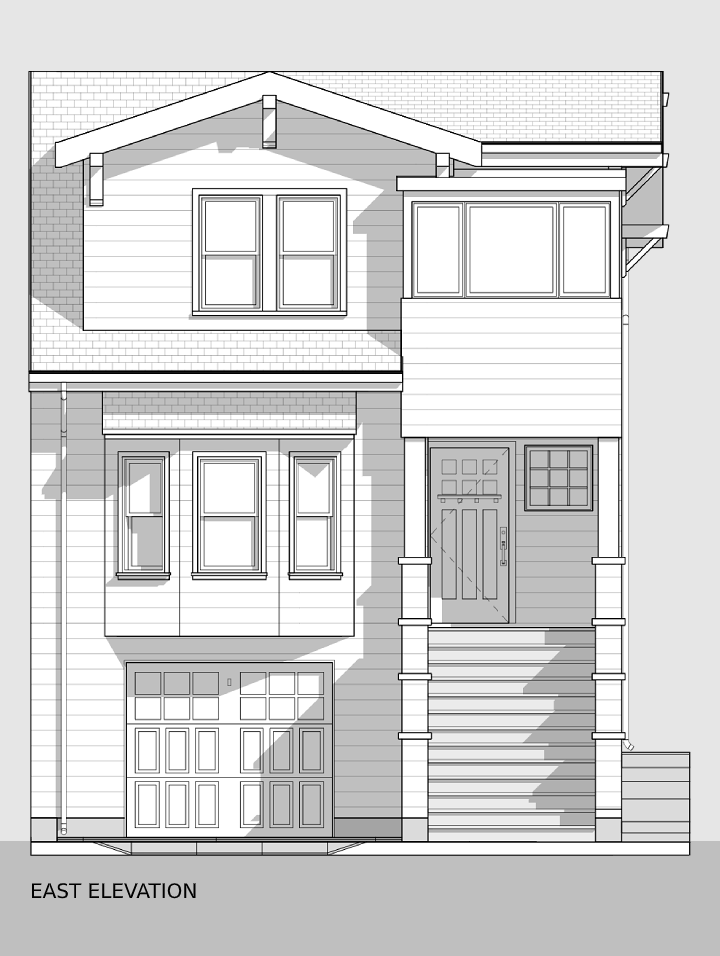

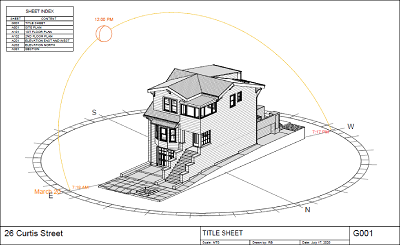

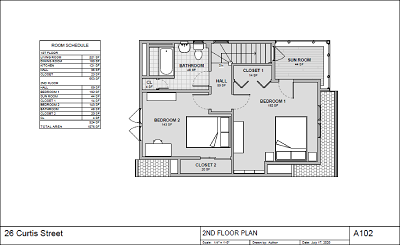

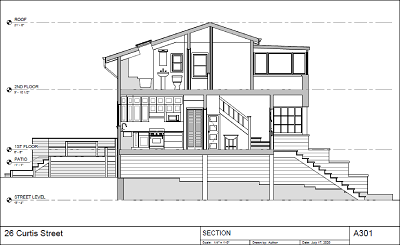

26 Curtis Street Drawing an existing building in Revit is a great way to reinvigorate your drafting skills. This home has been remodeled several times and it is full of custom details - the perfect case for exploring Revit off the beaten path. Click here to view the 11"x17" drawing set |

|

|

|

Azuma House Architectural Visualization and Mobile VR

This project explores mobile VR in an architectural context.

|

||

|

|||

|

26 Curtis Street Deck Design and Construction, 2017 Designing a new deck off the back of our house was a unique opportunity to create a spacious extension of the dining room.

|

||

|

|||

|

|

||

|

YouTube Channel Teaching I started making video tutorials late 2012 to support lectures and workshops. Today the channel more than 50 tutorials, 5,600 subscribers, and close to 2M views. Techniques covered:

Visit my YouTube channel at http://youtube.com/rubenborup |

|

Experiment R Teaching: Workshop on robotic fabrication This four-week workshop was using robotic hotwire cutting for creating polystyrene molds for concrete casting. A topology optimized design is created in solidThinking Inspire.

The model is then imported into Rhino and remodeled as NURBS geometry.

I order to create the molds, the NURBS model is split into segments and translated into ruled surfaces, needed for hotwire cutting.

This is achieved using custom Grasshopper scripts and some manual modeling in Rhino. Once the mold geometry is created, it is converted to robot code using HAL for Grasshopper. The molds are cut using a hotwire mounted on an industrial scale ABB IRB 6620 robot. The full size sculpture, measuring 3x21 meters (10'x70'), was cast and assembled by Hi-Con A/S. Read more |

|

Little Big Thing Teaching: Workshop on Site Registration and Laser Scanning This site registration consists of 45 laser scans and has a total of 701M points. The point cloud was used by the students as a reference model for designing site-specific art installations with the purpose of activating the space. After being introduced to the gear, the students were able to perform the majority of the laser scanning themselves using the Faro Focus 3D laser scanner. The scans were loaded and aligned in Faro Scene and finally filtered and rendered using Bentley Pointools. Portions of the 16 GB point cloud were loaded into Rhino and used for precisely measuring and for modeling site specific features. For more information about laser scanning see my laser scanning video playlist on YouTube. |

|

Tektonik Optik Teaching: Workshop on Topology Optimization and Digital Fabrication This is the result of a three-week workshop for 36 second-year students at Aarhus School of Architecture. The students were given a set of design criteria (span, height, supports). Next, the students would create a three-dimensional design space for topology optimization. By adjusting supports and loads, several iterations were made until we reached desirable results. After reviews, the designs were revised and modeled in Rhino using T-Splines, then sliced, numbered and laser cut in 4mm plywood. All models were assembled by hand. Techniques covered:

More info: Watch the video or read the publication |

|

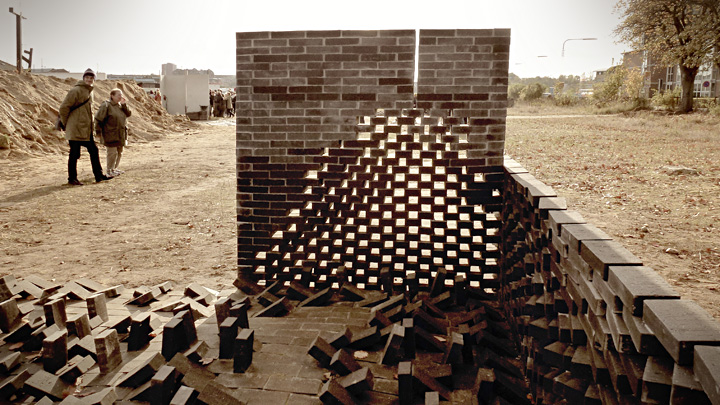

Bricks Teaching: Workshop on parametric design and masonry This four-week workshop introduced first-year students to masonry. By mixing traditional craft with visual scripting in Grasshopper, the students were able to explore and control parametric, rule-based systems containing hundreds of bricks in real-time. Techniques covered:

More info: Read the publication |

|

Architectural Parametrics Teaching: Workshop on parametric design and laser cutting The focus of this workshop was to investigate light and spatial conditions in relation to a specific site through the use of parametric design. In addition, the parametric system facilitated material use; materials cost, and live fabrication drawings. By combining mass fabrication with digital fabrication, it was possible to achieve highly individualized designs and build a full-scale design in only three days (+ design phase). The final structure consists of 3,648 parts of which 1,026 are digitally fabricated using laser cutting. As part of the workshop, a group of students would document the process. For more information, watch the video or read the publication |

|

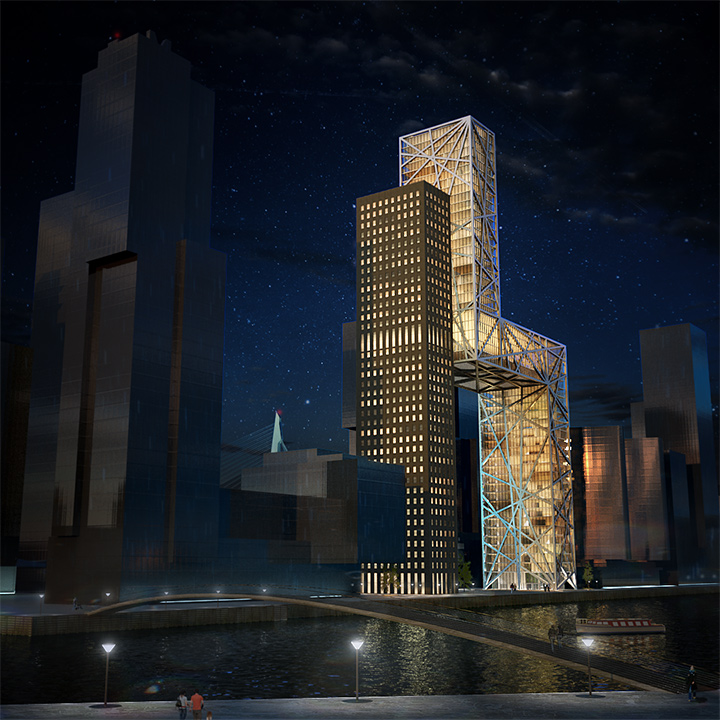

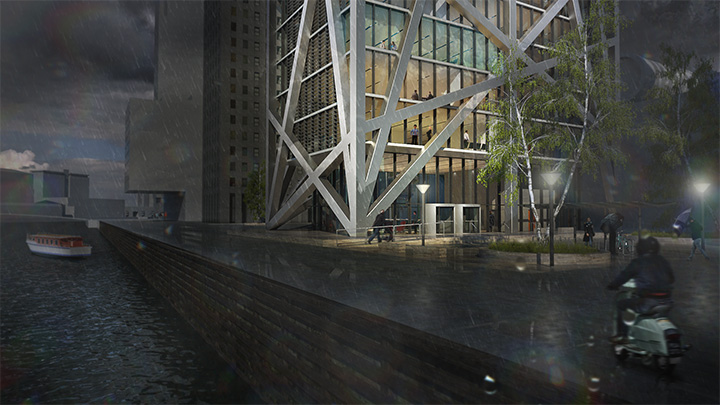

Multifunctional skyscraper Architectural Visualization, 2014 Revisiting my Master's thesis project from 2008; a multi-functional skyscraper. The project is located on Wilhelmina Pier in Rotterdam (The Netherlands) among buildings designed by Foster+Partners, Renzo Piano, and OMA. http://www.wilhelminapier.nl/en/architecture/ Based on the original concept, I cleaned up the geometry and applied new rendering techniques and weather conditions. |

|

|

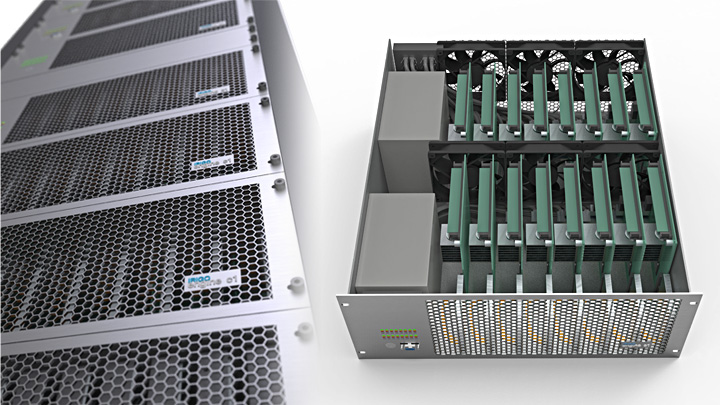

Irigo Engine Rack Units Product design and visualization, November 2011 The objective was to design a full server rack with two custom rack units for the Irigo Engine. More info: Read the brochure Project update: The design has undergone some changes, but the general concept is unchanged. More info about Cabo's Irigo Engine here |

|

|

|

Vestas V112 3.0 MW presentation video Product launch presentation animation, 2009 This video was made for the European Wind Energy Conference (EWEC) in Marseilles, 2009. For the release of their biggest wind turbine, Vestas asked Cadpeople to come up with a story that would highlight key features of their new flagship wind turbine. I organized storyboarding and worked on scenography design as well as modeling and animation. The project was created in three weeks.

|

||||||||

|

|

|

New Orleans Master's Thesis Project, June 2008 My thesis project is situated on Wilhelminapier in Rotterdam, home of the Holland-America Line Terminal, for more than 100 years. The pier is transforming into a mini-Manhattan and my project is named New Orleans after the warehouse initially situated on the site. For information about the design process, watch this slideshow |

|

|